Automatic Roll Air Filter for Data Centers, New Energy, and Automotive Applications

$3 000.00

Roll Air Filter

Automatic Roll Air Filter for Data Centers, New Energy, and Automotive Applications

Automatic Roll Air Filter for Data Centers, New Energy, and Automotive Applications

Store Link: https://www.haiwos.com/ ***Product Details (***Please Sign In or Login to "My Account". Price is the EXW Factory Term price or send email to us get discount if possible and get shipping cost for delivery by CIF/C&F/FOB term: sales@hiclover.com***) WhatsApp on Mobile: +8613813931455

Automatic Roll Air Filter for Data Centers, New Energy, and Automotive Applications

Market-Driven Deployment of HICLOVER Solutions Across the North American Region

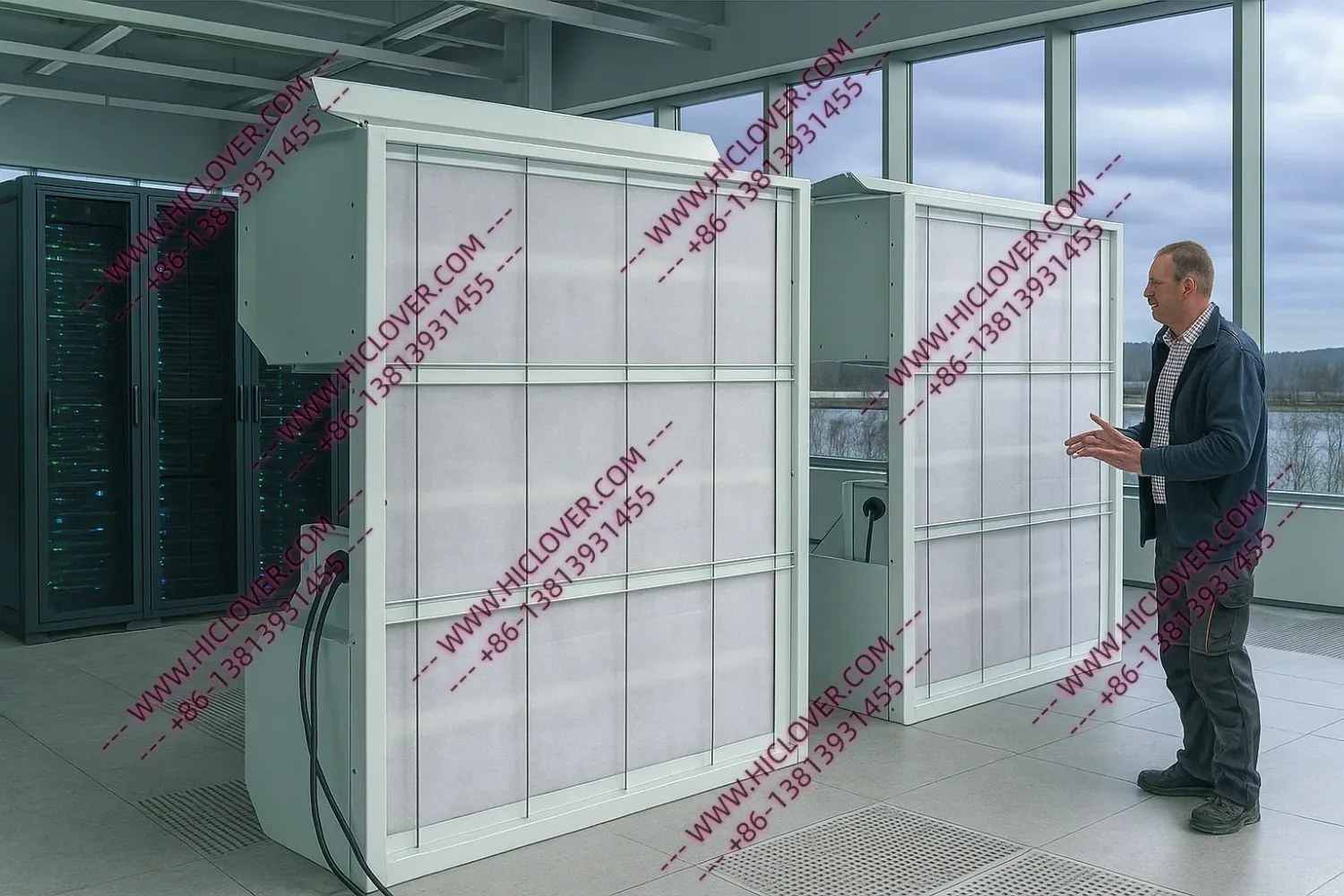

The Automatic Roll Air Filter from HICLOVER is engineered for high-duty industrial air-handling environments where particulate load is constant, operational uptime is critical, and maintenance windows are limited. Across data centers, the new-energy sector, and the automotive industry, this system provides a scalable, automated, and cost-efficient filtration solution tailored for North America’s rapidly expanding infrastructure in the United States, Canada, and Mexico.

1. Market Context: Why Automatic Roll Filters Are Increasingly Needed

1.1 Data Centers

North America hosts one of the world’s largest concentrations of hyperscale and colocation data centers. With thousands of racks generating continuous heat, precise temperature and air-quality control have become mission-critical. Particulate infiltration—from urban dust to seasonal wildfire smoke—poses thermal, electrical, and corrosion risks to sensitive IT gear. Traditional panel filters require frequent manual replacement and pose downtime risks.

1.2 New-Energy Industries

Battery-manufacturing plants, EV-module facilities, hydrogen-system workshops, and grid-scale energy-storage factories demand consistent, high-volume air filtration. These facilities operate clean-production workflows where dust load is variable but often heavy, especially in early-stage cell manufacturing, electrode mixing, surface-coating, and pack assembly.

1.3 Automotive Manufacturing & Paint-Booth Systems

North American automotive production—including U.S. Midwest clusters, Ontario’s automotive belt, and Mexico’s rapidly expanding OEM and Tier-1 supply chain—relies heavily on controlled-environment air management. Paint booths, robotic welding zones, machining halls, and assembly lines require efficient coarse and pre-filtration to extend the life of downstream filters and maintain output quality.

In each of these environments, HICLOVER Automatic Roll Air Filters deliver a unified filtration platform that responds to the operational demands of high-flow industrial HVAC systems.

2. Core Features of HICLOVER Automatic Roll Air Filters

Automated Media Advancement

A PLC-controlled mechanism automatically advances the filter roll based on differential pressure readings. When the preset threshold is reached, the system autonomously feeds new filter media into place.

This eliminates manual checks, reduces labor requirements, and ensures that airflow remains stable.

High-Efficiency G3/G4 Filtration Media

The filter rolls utilize EN 779 G3/G4-grade or MERV-equivalent media, offering strong dust-holding capacity and stable performance even in high-volume intake operations.

Continuous Operation Without Shutdown

Because the filter media is replaced automatically in-line, no system shutdown or HVAC downtime is required. This is critical for:

- always-on data centers

- 24/7 battery factories

- automotive production lines with takt-time constraints

Modular Design for Large HVAC Systems

Available in multiple configurations—single-stage, dual-stage, and custom width modules—allowing integration with large rooftop units, air-handling units (AHUs), or centralized ventilation systems.

Low Maintenance & Long Service Life

The system reduces overall filter usage by optimizing media consumption and eliminating premature changes. Mechanical components are designed for long-term durability in dusty or corrosive environments.

Optional IoT Monitoring

Integration with BACnet, Modbus, or cloud monitoring enables remote supervision across large-scale facilities, supporting modern North American energy and IT facility management requirements.

3. Application Advantages in the Data-Center Sector

Superior Particulate Protection for Sensitive Electronics

The system provides constant, stable intake airflow, protecting data-center cooling coils, CRAC units, and servers from particulate overload—especially during wildfire-smoke seasons in California, Canada’s BC region, and the U.S. Southwest.

Reduced Manual Labor

Data centers typically require frequent filter changes. With the HICLOVER automatic roll system, replacement cycles are eliminated, minimizing on-site labor and improving operational continuity.

High Availability

The key performance metric in data-center operations is uptime. HICLOVER’s automated system supports uninterrupted operations, reducing the risk of thermal events linked to airflow restrictions.

4. Advantages for the New-Energy and EV-Manufacturing Sector

Stable Pre-Filtration for Clean Manufacturing Zones

Proper dust suppression is essential for coating, mixing, and assembly rooms. Automatic roll filtration ensures a uniform airflow profile, improving consistency in material deposition and battery pack assembly.

Resistance to High-Dust Loads

New-energy facilities produce dust from cathode/anode processing and metal-cutting activities. The high dust-holding capacity of G3/G4 rolls allows for extended periods between media advancement cycles.

Flexible Integration With Large-Volume Air Systems

Battery factories use many large AHUs. HICLOVER’s modular, roll-filter units integrate seamlessly with high-CFM air-handling equipment found throughout U.S. and Canadian EV-plant clusters.

5. Automotive Industry Deployment in North America

Improving Paint-Booth Quality

Paint booths rely on stable pre-filtration to reduce dust inclusions and rework rates. Automated roll filters guarantee consistent media freshness.

Extending Downstream Filter Life

By capturing coarse dust effectively, downstream HEPA or fine filters last longer. This yields significant cost savings across high-output automotive plants in Michigan, Ontario, and Mexico.

Enhancing Airflow During Robotic and Welding Processes

Robotic welding areas generate metal fumes and particulates; stable intake airflow is essential for fume-extraction system efficiency. Automatic roll filters maintain that stability.

6. North America Market Opportunities

United States

- Massive growth in hyperscale data centers (Virginia, Texas, Ohio, Arizona)

- Expanding EV-battery clusters (Georgia, Tennessee, Kentucky, Nevada)

- Automotive OEM hubs (Michigan, South Carolina, Alabama)

Canada

- Ontario’s automotive corridor

- Data centers near Toronto and Montreal

- Emerging clean-energy manufacturing and battery-material refining

Mexico

- Strong automotive supply chains (Nuevo León, Guanajuato, Puebla)

- Increasing EV-component manufacturing

- Expanding Tier-1/Tier-2 facilities requiring efficient air systems

Across all three markets, labor costs, safety requirements, and uptime expectations make automatic filtration increasingly preferred over manual filter systems.

7. Summary

The HICLOVER Automatic Roll Air Filter aligns with the evolving industrial landscape of North America—where 24/7 operations, energy-efficient design, and reliable airflow control are essential. Its automated, PLC-driven filter-advancement system provides a long-term, low-maintenance solution for large facilities in the data-center, new-energy, and automotive sectors. With its integration capabilities, strong durability, and cost-saving performance, it represents a forward-looking filtration platform suited to the region’s demanding standards.

If you want, I can also prepare:

- A shorter marketing brochure version

- A technical datasheet version

- A North America-specific SEO article with optimized keyword clusters

- A version including internal links to cloverfilter.com

Display prices in:USD